LOOKING FOR A GEOTHERMAL SOLUTIONS COMPANY?

CONTACT USWhat We Do

Trench layout, dig or excavate trench to appropriate depth, apply bedding materials such as sand for pipe protection against sharp or large objects like rocks.

If large rocks come from the excavated trench they will not be put back in trench and also some locations or contractors require trace wire.

Backfill procedure once the loops are fused into header they will be tested up to 100 psi for leaks.

Backfill procedure will be followed as specified on the specifications book.

Building interior, loop fusion into header supply and return lines.

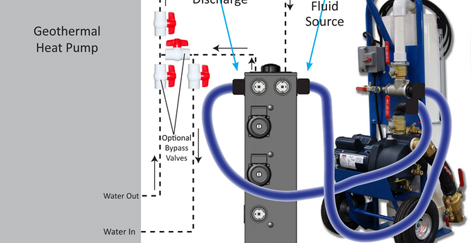

Flushing, cleaning lines and air removal of system.

This is one of the most important procedures that needs to be followed in order for the system to function properly.

Flushing: removal of all debris such as dirt, sand, pipe shavings, teflon tape and other items that can get in the pipe during the fusion process.

Purge: removal of air trapped in the lines vertical and horizontal since the loops can go as much as 300ft down into earth and the water needs to be moved at a certain speed to push the air out of the pipes.

Pump installation and pump replacement: some water source heat pumps come with a built in pump and some do not so they are to be mounted in a close proximity of the unit.

Circulating pumps eventually have to be changed either because they will just go bad or with the years of service they would start getting clogged up because of minerals in the water . In the event to replace the circulating pump the system would have to get flushed and purged to have the system back performing properly.

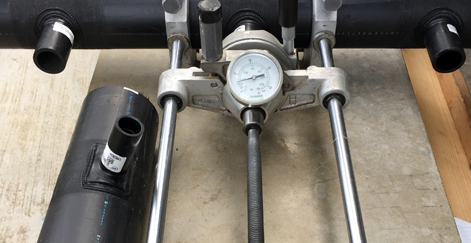

Purge ports and purge valves replacement: a few years ago geo contractors used brass ball valves on exterior purge box and they would only last a few years then they had to be replaced.

There are many systems in place with these type of valves and pipe manufacturers make a valve made of the same material (polyethylene) and it can be buried or be installed in a purge box and it will last forever.

This is a fusion procedure and it would vary from 1-1/4 pipe up to 8″ pipe that is on the main pipe and the branch would go from 3/4″ up to 4″

1″-1/4 – 3/4 | 1-1/4-1″ | 1-1/2-3/4″ | 1-1/2-1″| 1-1/2-1-1/4 | 1-1/2-1-1/2 | 2″-3/4″ | 2″-1″ | 2″-1-1/4″ | 2″-1-1/2″ | 2″-2″ | 3″-3/4″ | 3″-1″ | 3″-1-1/4″ | 3″-1-1/2″ | 3″-2″ 3″-3″ | 4″-3/4″ | 4″-1″ | 4-1-1/4 | 4″-1-1/2″ | 4″-2″ | 4″-3″ | 6″-3/4″ | 6″-1″ | 6″-1-1/4″ | 6″-1-1/2″ | 6″-2″ | 6″-3″ | 6″-4″ | 8″-3/4″ | 8″-1″ | 8″-1-1/4 | 8″-2″ | 8″-3″ | 8″-4 | 8″-6″